The JVice Story

By Jay Smit

I was born on a farm in the Howick area and, from an early age, started dismantling and repairing things mechanical, from water pumps to tractors and was taught by my father to use the machinery in the farm workshop. Later I studied electronics and worked for Eskom, South Africa’s electricity-supplying parastatal, for 17 Years. After this I joined a door manufacturing company in Durban, my home city, as General Manager and was soon modifying and building custom automated machines to enhance production. These proved so successful that I was promoted to Technical Director for the entire Group and set up a small division that built specialized production machines. All the skills gleaned during this time stood me in good stead when I started building my own vice.

I started fishing at an early age and recently found a photograph of myself in a family album with a Toby, a small puffer fish, caught on a little spinning rod and reel. My father, a dedicated shad angler, took us on our annual vacation down the Natal South Coast every July. I have many happy memories of fishing outings with him over the years. In my twenties I discovered fly fishing in the salt and bought myself a six weight outfit. I could not have had much success because this rig disappeared amongst the junk in my garage for many years.

In April 2001, our family was invited by friends, Jill and Geoff Dettmer, for a short vacation in the Drakensberg Mountains of Natal. I was told to bring along a fly rod. After rummaging around in the garage for a while, I found the old six weight rod and reel and packed them into the back of the SUV.

When checking in at the venue, we were told that purple woolly buggers had worked well the previous weekend. They were on sale at the desk so I bought a few. Geoff donned his frog suit as my wife calls it and sailed off in his float tube - soon landing his first fish. I found a spot on the bank, the only place with no obstacles behind me and started flogging the water. Well, as the day progressed, I hooked less and less grass behind me and finally managed to actually get the woolly bugger into the water. The day was long and hot and I did not believe that it was possible for me to catch a fish on a fly. I persevered … at least I was starting to enjoy the casting even if there were no fish around. And then it happened - a 1.5 kg rainbow took my woolly bugger and was soon landed. A few minutes later another one and I was hooked for life. There and then I decided that this was the way to fish and that I was going to make my own flies - how difficult could it be anyway? Since that day all my surf rods and reels have been packed away and smelly bait has become something of the past - much to my wife’s delight. What she did not know was that worse was to come, total addiction to fly fishing. She is still trying to find a holiday destination where I cannot fish but, in vain. Wherever we go, I manage to find some water with fish that will take a fly.

When we got back from that first trip I rushed out and bought an entry level, rotary vice. That cheap and nasty vice is the main reason that the JVice came into being. Everything was wrong with the vice, it did not rotate smoothly and would not hold a hook. I got so angry I threw it into the bin and embarked on a project to build my own vice. First, plenty of research on the internet, then some rough drawings and I disappeared into my workshop. (No garage in our home, cars sleep outside) Many hours later I had version 1 complete. It was OK, it held a hook and rotated smoothly. I tied flies on it for a few weeks making notes all the time. Version 2 was better and, finally, version 3 was pretty useful and worked to my satisfaction.

It was about this time that I joined the Durban Fly Tyers (http://www.durbanflytyers.co.za/) and this is where my fly tying skills improved dramatically. One can learn just so much from the internet, but the practical tips and advice from other tyers speeds up the learning process by leaps and bounds. My advice to any one starting out is to join a club if possible. The friendships made there, the camaraderie and the fishing outings have been very enriching.

In October 2002 I booked to go on an Ufudu outing to Mtentu on the coast of the Eastern Cape with salt water guide, Ben Pretorius. – www.ufudu.co.za. This was a wonderful experience and it was here that I landed my first Kingfish over 50 cm which was the cherry on the top of a great trip.

Ben was very impressed with my vice and asked me to produce more as he was looking for products manufactured in South Africa to add to his range of fishing gear. The vice had taken more than 40 hours to produce by hand and I told Ben he was crazy to even think along those lines as the vice would be too expensive. Ben persisted and carried on nagging me until I eventually gave in and went to see a friend of mine who owned and ran a CNC workshop. We made some changes to suit his machines and I had to dig deep to find the money to order the minimum batch of 50 sets of components. A few weeks later I picked up the boxes of components and the first JVices were put together in November 2002. There were a few hiccups and the main stems were not to my liking and had to be remade to a new design. A deeper dig into my dwindling funds…

In February 2003, Ben sold the first JVice to Dr Sakkie Bezuidenhout, a brain surgeon from Pretoria, who attended one of Ben’s Kosi Bay trips and, in the same month, sold two more. Things were looking up. By the end of that year 37 vices had been sold and the prospect of recovering my original investment no longer seemed remote.

In September 2003 Gerard Barnardt of Cape Town (who had seen the JVice at an Ufudu Hookup meeting in Stellenbosch) kindly put me in touch with Hans Weilenmann, one of the world’s leading authorities on fly tying whose website, http://www.danica.com/flytier/, is essential reading for fly tyers. Hans was impressed and agreed to do a revue of the JVice in what is arguably the world’s leading English language fly fishing magazine, the American publication Flyfisherman, http://www.flyfisherman.com.

Here is what he wrote:

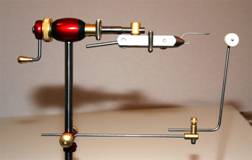

South Africa might not be the first location that comes to mind when considering a new vise, but it is indeed the origin of the JVice. The design follows that of the classic in-line rotary, and comes handsomely packaged in a black cordura nylon travel bag holding the vise, a bobbin cradle, a material spring, the oak tying station and a cloth waste bag.

The jaws are of the cam-operated, parallel clamp design, with a knurled knob near the tip for hook wire gauge adjustment. The vise is equally suited for right or left handed tiers, and the jaws are even easily inverted to have the adjustment knob situated on the near or far side of the jaws, depending on the tier's preference. The inside of the jaws are finely pebbled and there is a single hook pocket for holding big irons. The hook pocket is curved to follow the generic shape of a hook bend, and hooks of all sizes are held securely. Access to the smallest of hooks is somewhat restricted due to the beefy nature of the jaws.

The jaws are cam operated, where the cam works to close the jaws by either rotating it up or down. On the vise I tested, the cam could do with a shorter lever. Canting it upwards made it come into contact with the horizontal arm. (In discussion with the maker it became clear that the lever length issue has been rectified.) The jaws are finished in a pleasing non-reflective satin nickel.

The height of the jaws can be adjusted somewhat by canting them, with the aim of centering the hook shank exactly in line with the axis of rotation. However, the range of adjustment is quite limited and falls short of achieving in-line on large hooks such as pike hooks, large salmon irons or saltwater hooks. In the 'real world,' this is not a real issue and for me is no cause for concern. Exact in-line positioning is a must only for spinning vise designs. Close to axis is perfectly adequate for hand cranked rotary vises such as this.

Rotary friction is adjusted by a large diameter brass knurled ring, located at the back of the oval shaped bearing housing. The range of settings is wide enough to accommodate the tier's preference and, once set, the tension remains consistent. The rotary lever is brass and slightly angled away from the standrod. It is nicely shaped with a widening at the end to stop the finger from sliding off the lever, but somewhat short in length at just over one inch. I believe in future runs a somewhat longer lever may be fitted.

The supplied standrod is a non-standard 10mm in diameter. Upon request the vise can be delivered with a more standard 3/8" diameter, allowing third-party accessories to be more easily used.

The JVice is supplied with an oak wood tying station (14.5" x 10.25"), which doubles as a pedestal base. It rests on four silicone feet. The vise can be positioned on the tying station in a number of locations, making for a versatile setup. The height of the jaws above the tying station varies from 8" to 8.5", depending on the jaws angle set. Aside from placing the tying station on a flat surface, it also makes it very convenient to tie flies with the station positioned on one's lap. The tying station also has slots to hold tools and materials. The cordura nylon travel bag incorporates pockets for tying tools, as well as holding the tying station, vise and accessories.

Verdict:

The overall appearance of the JVice is one of solid workmanship, close tolerance machining and sound selection of materials used. If anything it leans towards a slight overkill in robustness, but that is hardly a bad thing. The lines are not quite as clean as I would like, with a few projections which, depending on how you position the non-bobbin hand, may cause interference. There are still some rough edges to the vise design, but the maker is addressing most of those I encountered. The result should be a sturdy, well-rounded vise. The inclusion of the tying station may be an added selling point depending on your tying requirements. The JVice has a black anodized ovoid bearing housing, but can also be ordered in red or blue upon request. The price of US $350 includes shipping from South Africa.

The vice has undergone considerable evolution since this revue. The Gooseneck is now the standard vice and gives considerably more hook height adjustment and hand access. The original double action cam for clamping the hook has been replace by a three-stage uni directional clamping action, upward toward the gooseneck. The rotating lever has been replace (by popular demand) with a crank. 3/8” stem remains a problem for me because 3/8” stainless steel is unavailable in SA but I do make a 3/8” adaptor to take fittings that will not fit on the 10mm stem.

The current JVice is made from solid brass for all the thumbscrews and adaptors, 316 stainless steel for the main shaft and bar stock aluminum for the main housing bushes and fittings (these are anodized black as standard with red and blue as options) The bushes which act as clutch and brake mechanism in the main housing are turned from Ertalite. This is an extremely durable material used for bushes and bearings in heavy machine engineering and gives the smooth clutch action when setting the large thumbscrew. The jaws are made from tool steel and hardened to Rockwell C55 after which they are finish ground and treated to get the required satin finish when the nickel plating is applied.

Shortly after the Weilenmann revue was published, the first export order went to Peter Frailey from Carlisle, MA in the US. He has an interesting website, www.fishingwithflies.com. He was so impressed he did a revue on the JVice and placed it on his site. Since then export orders have been regular with an average of one being sold abroad each month.

Once orders started coming from abroad I realized that I needed to set up a website. Having grown up in the electronic industry, I had worked with computers for many years and, as a gadget junkie, am fascinated by new technology. So the thought of building my own website – www.Jvice.com - was a challenge I revelled in. Photography is another hobby of mine, so I combined the two and built a simple website to promote the JVice. Unfortunately time is my worst enemy and I don't give the website the time it requires. I am also the webmaster for the Durban fly tyer's website www.durbanflytyers.co.za and this normally takes preference as there are monthly deadlines to be met as I photograph the fly of the month, write up the recipe and then publish on the website.

In February 2002, Maitland Knott, proprietor of South Africa’s oldest specialist fly fishing shop, The Flyfisherman in Hilton, Natal – www.theflyfisherman.co.za - asked me to send a vice down to the Ed Herbst in Cape Town. Ed is editor of South Africa’s oldest flyfishing magazine, Piscator, extant since 1948 and journal of one of the country’s most venerable flyfishing institutions, the Cape Piscatorial Society (www.piscator.co.za). Ed had promised to do a revue for the local magazine, Flyfishing – www.africanangler.com. This is when my troubles started because Ed, probably the country’s leading authority on ultra light line fly fishing and micropatterns, wanted midge jaws and provided me with a lot of research on the features that would enhance the tying of small flies. Well, to cut a long story short and after about 12 prototypes and many sleepless nights, I finally came up with a workable solution. One of the problems was to attach the midge jaws to the original JVice. To do this, I bent a piece of 8mm stainless steel in a U shape. The result was a bit ungainly but it worked. I have to give Ed a lot of thanks for his continual support and encouragement, It was really great to finally meet him and spend a day fishing the Holsloot stream near Worcester in the Western Cape (www.trouthaven.co.za) with him a few months ago.

Duncan Nebbe, a tyer living in Ghana, ordered one of the first midge jaws and was so taken by its U-shaped attachment for the midge jaw that he urged me to do the same for the standard jaw. At first I was reluctant because I thought the heavier jaws would badly unbalance the vice. I went ahead and made the first GooseNeck JVice and immediately fell in love with it. Even I, with my huge paws, could tuck my hands in behind the jaws. The hand access to the fly was so much better and more relaxed. The other advantage was that the jaws and fly, with a twist of the wrist, could be rotated back and forth a few degrees while holding the material in position. This is an invaluable benefit while making those first few critical and delicate wraps. Many of the original vices have since been upgraded to the GooseNeck version that has now become the standard - although the original vice is still available on request. In March 2005, Loren Williams, a tyer and fly fishing guide based in New York State, contacted me for a vice. He had a set of specific design requirements that I agreed to produce for him. Out of mostly standard components I put together what he, as a professional tyer, called his

Duncan Nebbe, a tyer living in Ghana, ordered one of the first midge jaws and was so taken by its U-shaped attachment for the midge jaw that he urged me to do the same for the standard jaw. At first I was reluctant because I thought the heavier jaws would badly unbalance the vice. I went ahead and made the first GooseNeck JVice and immediately fell in love with it. Even I, with my huge paws, could tuck my hands in behind the jaws. The hand access to the fly was so much better and more relaxed. The other advantage was that the jaws and fly, with a twist of the wrist, could be rotated back and forth a few degrees while holding the material in position. This is an invaluable benefit while making those first few critical and delicate wraps. Many of the original vices have since been upgraded to the GooseNeck version that has now become the standard - although the original vice is still available on request. In March 2005, Loren Williams, a tyer and fly fishing guide based in New York State, contacted me for a vice. He had a set of specific design requirements that I agreed to produce for him. Out of mostly standard components I put together what he, as a professional tyer, called his

“perfect vice”. Among other requirements he wanted a crank handle

(Pictures above show the old and new crank handles. Easily upgradeable) and the jaws to lock with an under jaws cam system. I produced a retrofit kit to fit the standard jaws and a crank handle for him. The crank handle has now become the standard and the under cam jaws are available on request. Later that year Loren was chosen as the official fly tyer for the US fly fishing team and accompanied them to the 2005 World Championships in Sweden. His website can be viewed at http://www.flyguysoutfitting.com/tyingtools.html. Loren did a great revue on his JVice on his site. Picture above taken off Loren’s web page.

(Pictures above show the old and new crank handles. Easily upgradeable) and the jaws to lock with an under jaws cam system. I produced a retrofit kit to fit the standard jaws and a crank handle for him. The crank handle has now become the standard and the under cam jaws are available on request. Later that year Loren was chosen as the official fly tyer for the US fly fishing team and accompanied them to the 2005 World Championships in Sweden. His website can be viewed at http://www.flyguysoutfitting.com/tyingtools.html. Loren did a great revue on his JVice on his site. Picture above taken off Loren’s web page.

In early 2005 Dean Childs of Wasatch Custom Angling Products in the USA contacted me. He was looking for a vice to add to his range of tying tools and Hans had put him in touch with me. Dean tested the JVice and chose it from a long list of vices to add to his range. Dean offers the GooseNeck JVice with a short 3/8: stem and the under jaw cam. This fits on his base and is sold as the Model J. Wasatch are closely associated with Regal who through Dean ordered a large quantity of my Tube Fly attachments to fit the regal vice.

http://www.regalengineering.com/Regal_Engineering/TubeflyVise.html

Because of the rising cost of components I decided to purchase a CNC lathe to enable in-house production of parts and to improve quality. The new machine arrived in early 2007 and, since installation, all parts except the two jaw pieces are produced in-house. The new machine has enabled me to test new ideas and expedite research and development where, previously, such work took months and I had to do big minimum runs. The new machine led to recent developments like the new tube fly attachment, backdrop card holder, articulated bobbin rest and deer hair packer to name a few. The inspiration for these new accessories has come from fellow members of the Durban Fly Tyer’s club and from customers but the idea of the articulated deer hair packer came to me one sleepless night when I had gone to bed weary and frustrated after tying half a dozen Muddler Minnows. It allows you to compact the spun hair and lock it quickly and securely in place with two turns of the vice handle placing thread wraps in front of the hair prior to applying the next pinch of hair. Without it, you would have to pick up and put down a hair compactor which is time consuming.

What the future holds I can’t say for certain - but development never stops. Responding to feedback from customers and interpreting their ideas has led to the development and manufacture of the attachment for tying Clousers ( as seen at right), articulated bobbin holders and a backdrop card holder. The vice keeps evolving. The basics have remained which makes upgrades, add-ons and customization easy. At the moment, looking at what else is on the market, I think it is fair to say that there is no vice available that is as versatile and multi-faceted as this one.

I love the variety fly fishing offers and genuinely have no preference. Hunting tiny trout in a small mountain stream gives as much pleasure as casting to Kingfish in the surf. The one element that I enjoy nearly as much as the fishing is the tying of flies before any trip and then tying flies on location in the evenings - trying new flies, tying up what worked for other anglers and trying to match the hatch or baitfish or whatever the fish are feeding on. Like my fishing I have no preference when tying fly’s and try and cover the full spectrum from the tiniest Midges to big 4/0 Flash Profiles. I also love fishing the gullies for small species in the salt when there are no game fish around. When there is not much wind I do this with the Sage TXL #00 or a 2 weight, but windy conditions normally prevent their use. Natal is a great place for a jack of all trades fly fisherman like me. With no more than a two-hour drive I have access to small mountain streams, still waters for trout and bass, bigger rivers for the Natal Yellowfish, Tigerfish up north at Josini Dam and, off course, the Indian Ocean on my doorstep. For trout and yellows - when conditions permit - dry fly is my first choice, then imitative nymphs and, if all else fails, I will resort to woolly buggers or other attractor patterns. My favourite rods are Sage, in particular the TCR series and, off course, the TXL "00".

I love the variety fly fishing offers and genuinely have no preference. Hunting tiny trout in a small mountain stream gives as much pleasure as casting to Kingfish in the surf. The one element that I enjoy nearly as much as the fishing is the tying of flies before any trip and then tying flies on location in the evenings - trying new flies, tying up what worked for other anglers and trying to match the hatch or baitfish or whatever the fish are feeding on. Like my fishing I have no preference when tying fly’s and try and cover the full spectrum from the tiniest Midges to big 4/0 Flash Profiles. I also love fishing the gullies for small species in the salt when there are no game fish around. When there is not much wind I do this with the Sage TXL #00 or a 2 weight, but windy conditions normally prevent their use. Natal is a great place for a jack of all trades fly fisherman like me. With no more than a two-hour drive I have access to small mountain streams, still waters for trout and bass, bigger rivers for the Natal Yellowfish, Tigerfish up north at Josini Dam and, off course, the Indian Ocean on my doorstep. For trout and yellows - when conditions permit - dry fly is my first choice, then imitative nymphs and, if all else fails, I will resort to woolly buggers or other attractor patterns. My favourite rods are Sage, in particular the TCR series and, off course, the TXL "00".

Well that’s the story of the evolution of the JVice so far. Many people ask, “What guarantee?” I tell them my product has a lifetime guarantee. My lifetime. Long live Jay!